INCOLOY 925 / UNS N09925

Common name: Chromium alloy 925; Alloy 925:

incoly®Alloy 925 (UNS N09925) is an age-hardened nickel-iron-chromium alloy with added molybdenum, copper, titanium, and aluminum.

incoloy®925 Alloy Description:

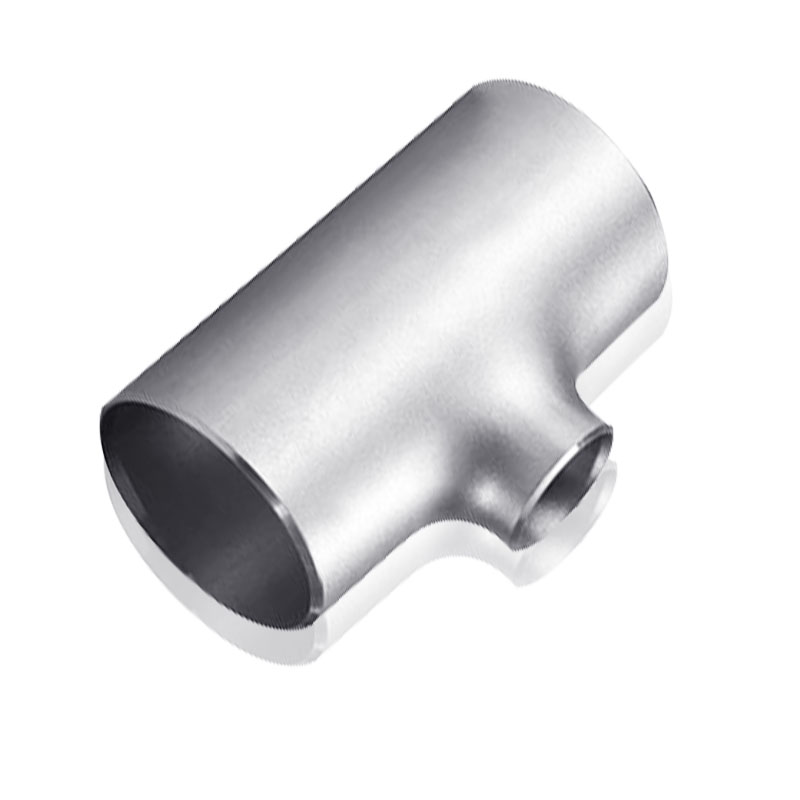

Incoly®925 alloys are used in a variety of applications requiring high strength and corrosion resistance. Due to its ability to resist sulfide stress cracking and stress corrosion cracking in “sulfur-containing” (H2S) crude oil and natural gas, the alloy can be used in downhole and surface gas well components, including pipe fittings, valves, hangers, landing tubes, tool joints, and packers. The alloy can also be used in fasteners, Marine and pump shafting, and high-strength piping systems

Product characteristics:

It has good mechanical strength and extensive corrosion resistance

Application field:

Downhole and surface components for acidic environments (containing hydrogen sulfide). Such as crude oil and natural gas production.

Performance characteristics:

Inconel stainless steel 925 is an inconel alloy. It also has the excellent strength and corrosion resistance of Inconel 825. It has good resistance to stress cracking and stress corrosion cracking in sulphide environment.

Similar brand:

| UNS | TRADEMARK | |||||||

| N09925 | INCOLOY 925 | |||||||

Chemical composition:

| Alloy | % | Ni | Cr | C | Mn | Fe | Si | Cu | S | Al | Ti | P | Mo |

| INCOLOY 925 | Min | 42 | 19.5 | – | – | Bal. | – | 1.5 | – | 0.15 | 1.9 | – | 2.5 |

| Max | 46 | 23.5 | 0.03 | 1 | Bal. | 0.5 | 3 | 0.03 | 0.5 | 2.4 | 0.03 | 3.5 |

Physical property:

| density | 8.14 G/CM³ | |||||

| Fusing point | 1343 ℃ | |||||

The minimum mechanical properties of an alloy at room temperature:

| Alloy state | Tensile strength | Yield strength | Rate of elongation | |||||

| RM N/MM² | RPO.2N/MM2 | A5% | ||||||

| Solid solution | 650 | 300 | 30 | |||||

Form