Incoloy 901 / UNS N90901 /

Incoloy® 901, NIMONIC® 901, Alloy 901, AISI 681, AISI 682, PWA 1002, PWA 1003, SPS M259, UNS N90901, AMS 5660, AMS 5661, B50A30628, DIN, 84B, 84B。

Incoloy901 Product description:

Incoloy901 is a solid solution-hardening deformed superalloy based on Fe-Ni-Cr, with metastable γ”Ni(Ti, Al) phase for aging strengthening, a trace of aluminum can inhibit the conversion of γ” to η-Ni3Ti phase. The alloy has high yield strength and lasting strength below 650℃, good oxidation resistance below 760℃, long-term use of stable structure. The alloy has a high yield strength below 650℃

Alloy 901 Chemical composition:

| % | Ni | Cu | Al | Fe | Ti | Co | Mn | S | C | Si | P | Cr | Mo | B |

| Min. | 40 | 2.35 | 11 | 5 | 0.01 | |||||||||

| Max. | 45 | 0.5 | 0.35 | Rest | 3.1 | 1 | 1 | 0.03 | 0.1 | 0.6 | 0.03 | 14 | 7 | 0.02 |

Alloy901 Physical properties:

| Density | 8.14 g/cm3 |

| Melting point | 1280-1345℃ |

Alloy 901 minimum mechanical properties in the room temperature:

| Status | Tensile strength | Yield strength | Elongation |

| Rm N/mm2 | RP0.2N/mm2 | A5 % | |

| Alloy901 | 1034 | 689 | 12 |

Specifications:

| bar | AMS 5661/AMS 5660 |

| forging/ring | AMS 5661 |

| wire | AMS 5830 |

Incoloy 901 alloy application:

The alloy is used in components in aircraft and gas turbines, such as turbine rotors, compressor discs, hubs and shafts, with a maximum operating temperature of about 1100ºF (595ºC).

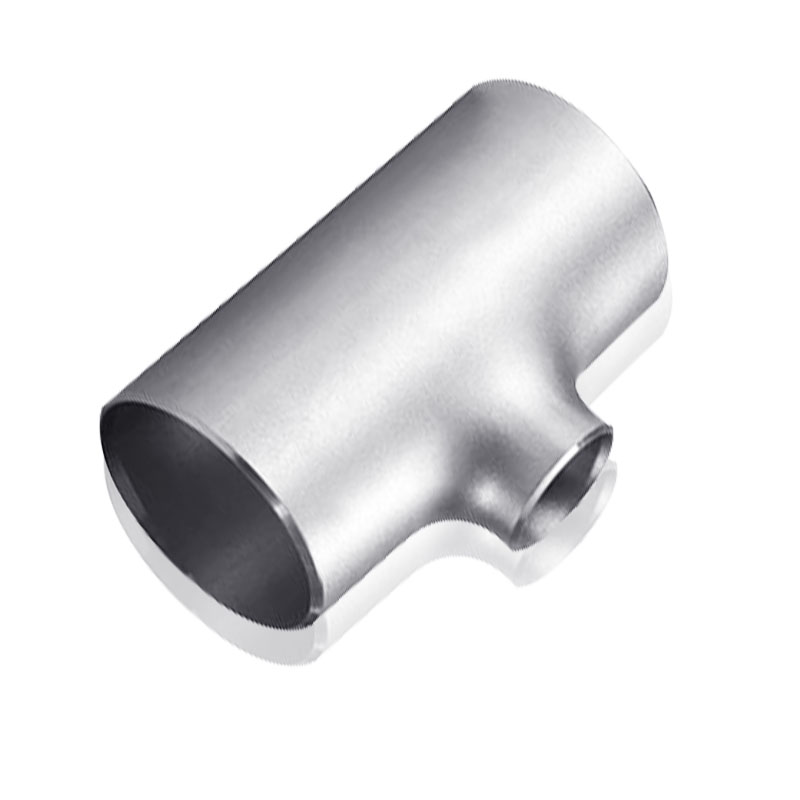

Form