Inconel 725 / UNS N07725

Inconel725 alloy is nickel chromium molybdenum niobium alloy, has excellent corrosion resistance, after aging heat treatment can greatly increase the strength of the alloy, can greatly improve the ductility and tensile strength of the alloy. The alloy also has strong resistance to stress corrosion.

Inconel 725 alloy description:

Inconel 725 (UNS N07725) is a nickel-based alloy that is highly resistant to many water-based environments and has extremely high strength age-hardening. It has essentially the same corrosion resistance as Inconel 625, which is widely used in a variety of corrosive environments.

Inconel 725 is particularly resistant to media containing carbon dioxide, chloride, and Liucide hydrogen, such as those encountered in deep acid gas Wells. In such an environment, it can resist general corrosion, pitting corrosion, liu compound stress cracking (hydrogen embrittlement) and stress corrosion cracking. Inconel 725 is also resistant to salt water and seawater corrosion.

The Inconel 725 meets the need for high temperature environmental fracture resistance in deep, extremely harsh oil and gas production environments. Due to the higher molybdenum content, it provides better cracking resistance at higher temperatures at higher levels of H2S.

Inconel725 chemical composition:

| Grade | % | Ni | Cr | Mo | AI | Ti | Fe | Nb |

| Inconel 725 | Min | 55 | 19 | 7 | 1 | Bal. | 2.75 | |

| Max | 59 | 22.5 | 9.5 | 0.35 | 1.7 | 4 |

Inconel 725 Physical characteristics:

| Density | 8.9g/cm3 | |||||||

| Fusing point | 1271℃-1343℃ | |||||||

Mechanical properties of Inconel 725 alloys at room temperature:

| Grade | Tensile strength | Yield strength | Rate of elongation |

| Inconel 725 | ≥1137 MPa | ≥827MPa | 20% |

Inconel 725 application area:

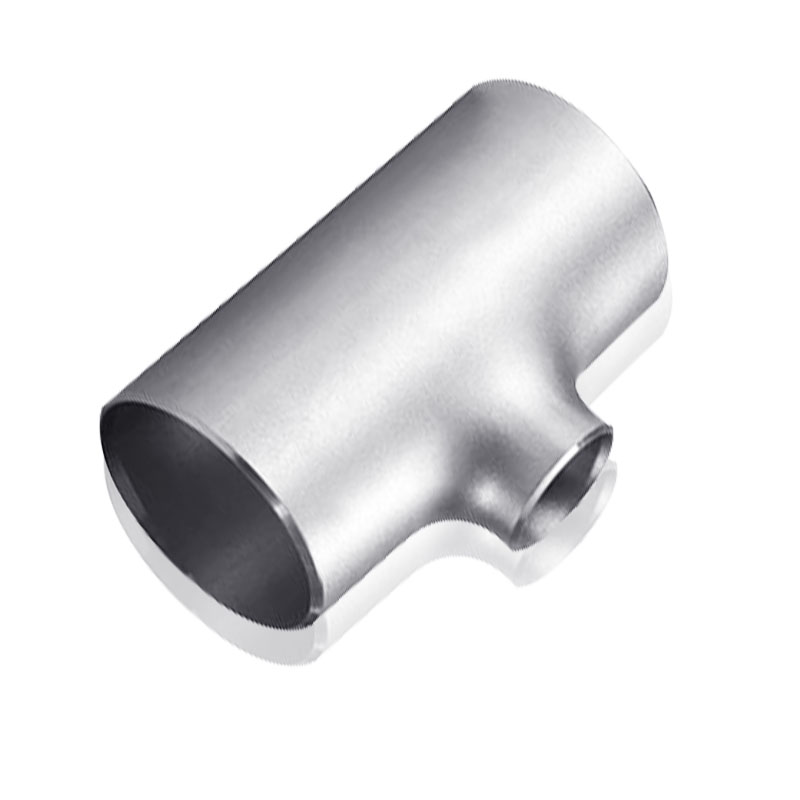

Used for pipe fittings, joints and bearings in acid resistant equipment. It is also widely used in Marine equipment.

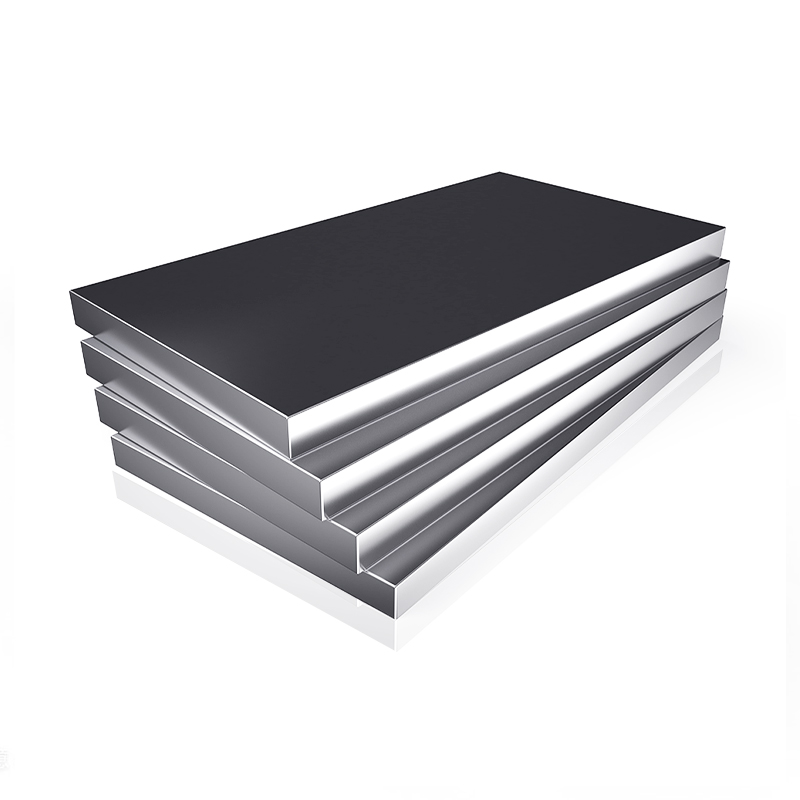

Form